Water Softner

A water softener plant is a specialized water treatment system designed to remove hardness causing minerals, primarily calcium and magnesium from water. It utilizes a process called ion exchange to exchange calcium and magnesium ions with sodium ions, effectively reducing water hardness.

The water softening process typically involves the following steps:

1. Dual Media Filtration: Dual media filters are commonly used in water treatment plants for the removal of suspended solids, turbidity, and fine particulate matter from water. These filters consist of two layers of different filter media, typically anthracite coal and sand, arranged in a specific order. The use of two different filter media with distinct particle size distributions provides a more effective filtration process by allowing for better particle capture and retention.

2. Resin Bed Preparation: The water then flows through a resin bed containing ion exchange resin beads. These resin beads are typically made of a polystyrene matrix coated with sodium ions.

3. Ion Exchange: As the water passes through the resin bed, calcium and magnesium ions present in the water attach to the resin beads, displacing the sodium ions. The calcium and magnesium ions are retained by the resin, while sodium ions are released into the water.

4. Regeneration: Over time, the resin bed becomes saturated with calcium and magnesium ions, and the water softening capacity diminishes. To regenerate the resin bed, a brine solution (sodium chloride) is introduced into the system. The high concentration of sodium ions in the brine displaces the calcium and magnesium ions on the resin beads, effectively rejuvenating the resin bed for further water softening.

5. Rinse and Backwash: After regeneration, the resin bed is rinsed and backwashed to remove excess brine, residual contaminants, and any accumulated sediment or debris.

6. Treated Water: The softened water is then ready for use and distributed to the intended application, whether it be for domestic, commercial, or industrial purposes.

Water softener plants can be designed to meet specific flow rates and water hardness levels based on the requirements of the application. They are commonly used in various industries, such as residential projects, hospitality, healthcare, food and beverage, and textile, where hard water can cause scaling, reduced efficiency, and equipment damage.

RO Plant

A reverse osmosis (RO) plant is a highly advanced water treatment system that employs a semi-permeable membrane to remove dissolved solids, contaminants, and impurities from water. It is widely used for purification of brackish water and the production of high-quality drinking water.

The RO process involves several stages:

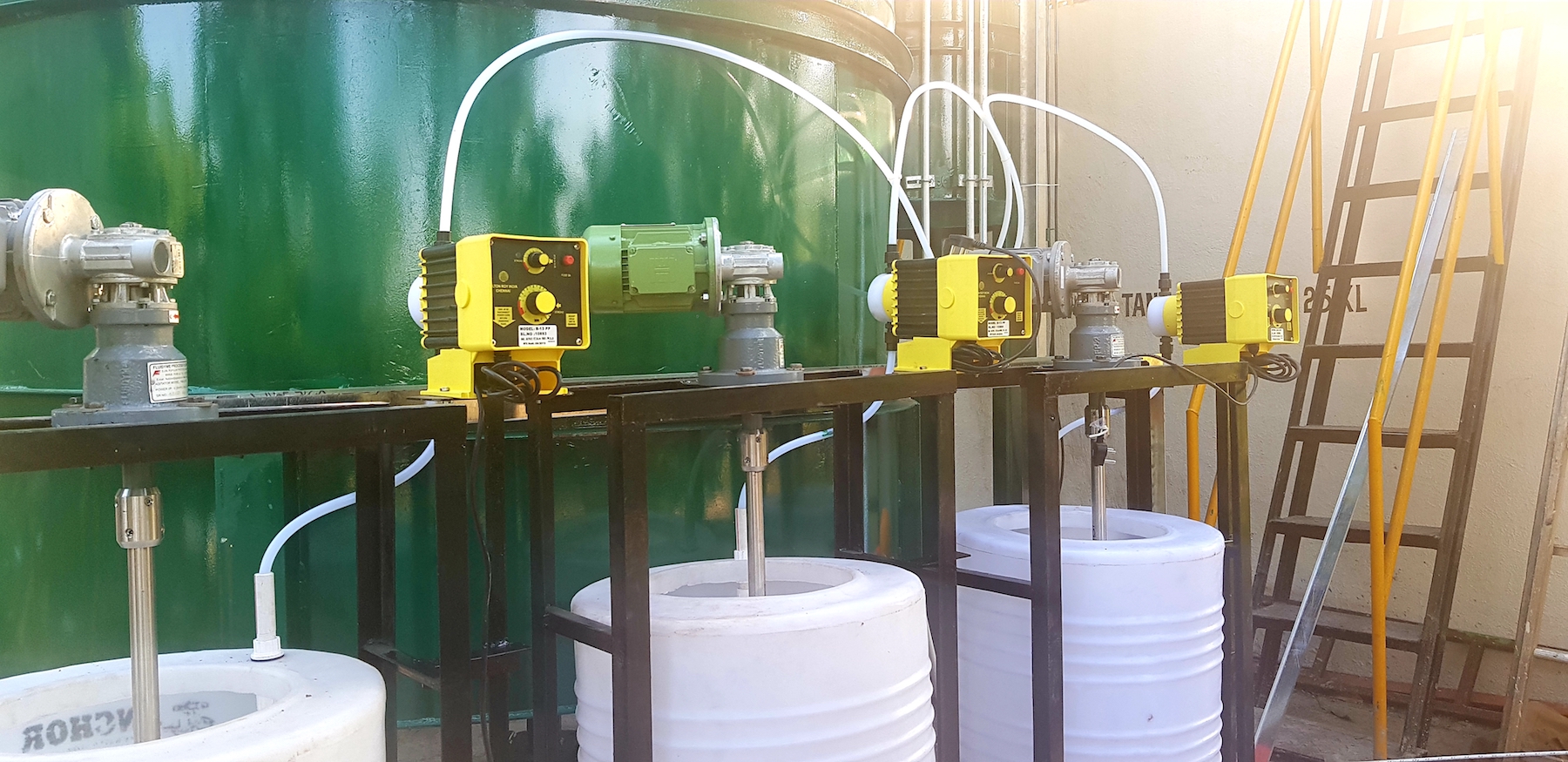

1. Pre-Treatment: Raw water undergoes pre-treatment to remove suspended solids, sediment, chlorine, and other impurities that could potentially damage the RO membrane. Pre-treatment typically includes processes such as filtration, sedimentation, and chemical dosing.

2. Pressure Pumping: The pre-treated water is pressurized using a high-pressure pump. The increased pressure helps overcome the osmotic pressure and forces water molecules through the semi-permeable RO membrane.

3. Membrane Separation: The pressurized water is then passed through the RO membrane, which acts as a barrier, allowing water molecules to pass while rejecting dissolved solids and contaminants. The membrane consists of tiny pores that only permit water molecules to pass through, effectively removing ions, salts, bacteria, viruses, and other impurities.

4. Reject Water Disposal: As the water molecules pass through the membrane, a portion of the feed water becomes concentrated with rejected impurities. This concentrated stream, known as the reject or concentrate, is discharged from the system and may require appropriate disposal or further treatment.

5. Permeate Collection: The purified water that successfully passes through the membrane is known as permeate or product water. It is collected and stored for distribution as high-quality drinking water or for various industrial applications.

6. Concentrate Recirculation (Optional): In some RO systems, a portion of the concentrate can be recirculated back to the feed water to improve overall system efficiency and reduce waste.

RO membranes can remove a wide range of contaminants, including salts, heavy metals, organic compounds, bacteria, and viruses, resulting in water of exceptional purity.

RO plants find applications in diverse sectors like residential complexes & industries, including desalination for coastal regions, potable water production, pharmaceutical manufacturing, food and beverage processing, power generation, and electronics manufacturing etc.